Abstract

This post describes the results of Finite-Element-Method simulations (using the software package FEMM) of the RF resistance at 7 MHz of various conductor shapes for use in a small transmitting loop antenna. The conclusion – already known from past theoretical literature, and verified here by simulation – is that a large-diameter, round-cross-section tubular conductor can be replaced with a square-cross-section conductor whose cross-sectional width and height correspond to the tube’s diameter, with negligible change in RF resistance. A new finding is that electrically isolating the four flat faces of the square-cross-section conductor from each other has negligible effect only if the four faces are perfectly aligned to form a perfectly-square cross-section; if, however, the four sides are slightly misaligned to form a distorted approximation of a square, then the RF resistance significantly increases due to uneven distribution among the isolated faces of the RF current which cannot redistribute itself due to the inter-face isolation. Electrically connecting the four flat faces of the square-cross-section conductor may, depending on the conductivity of the connecting material, reduce the RF resistance, by allowing current redistribution and compensating for an imperfect shape of the square cross-section. However, using tin (solder) as a connecting material was found to offer no benefit over leaving the faces disconnected.

Background: Round-cross-section vs. Square-cross-section conductors

As mentioned in a previous post (http://qrp-gaijin.blogspot.com/2017/09/a-1-meter-diameter-small-transmitting.html), H. A. Wheeler’s 1955 article "Skin Resistance of a Transmission-Line Conductor of Polygon Cross Section" already established that:

If a conductor cross section is any straight-sided polygon that can be circumscribed on a circle, it is found to have the same skin resistance as a conductor whose cross section is this circle. For example, a square wire has the same resistance as a round wire of the same radius, though the square perimeter is 4/pi times as great.To verify this, a number of Finite-Element-Method computer simulations were performed with the FEMM software.

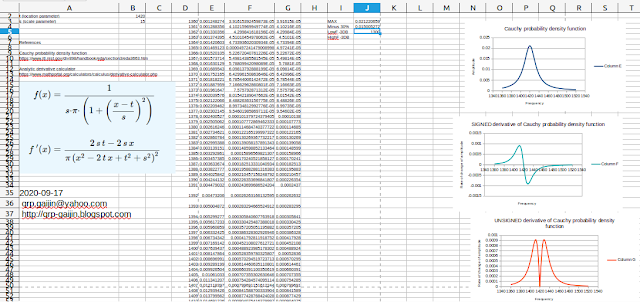

Analytically computed, the RF resistance Rloss at 7 MHz of a 3.14 meter length (corresponding to a loop antenna of 1 meter diameter) of round copper conductor having 10 cm diameter is 6.81 milliohms, as can be verified by the formulas and calculator at https://chemandy.com/calculators/round-wire-ac-resistance-calculator.htm. The identical result can also be found by assuming an equal current distribution along the entire conductor surface area (as will be the case if the conductor has a round cross-section and is not influenced by the magnetic fields of nearby conductors) and computing the RF sheet resistance of the conductor (https://www.microwaves101.com/encyclopedias/sheet-resistance) using the spreadsheet at https://www.microwaves101.com/uploads/RF-Sheet-Resistance-Rev-7.xls. Using that spreadsheet, the skin depth is computed as 24.60 microns, the surface resistivity per square for a conductor of 5 skin depths thickness is 0.685 milliohms, and for a sheet conductor of 3.14 meters length and 0.314 meters width, the number of squares on that sheet is 10 (3.14m / 0.314m), so the total RF sheet resistance is 10 squares * 0.685 milliohms/square = 6.85 milliohms, which is essentially identical to the previously-computed result of 6.81 milliohms.

Analytically computed, the radiation resistance Rrad of a single-turn, 1 meter diameter loop antenna is approximately 5.7 milliohms, using the approximate formula 31171*(A/lambda^2)^2 (reference: https://www.ece.mcmaster.ca/faculty/nikolova/antenna_dload/current_lectures/L12_Loop.pdf). Various small-loop calculators also return this same value of radiation resistance for a 1 meter diameter loop (reference: https://owenduffy.net/blog/?p=1693).

Therefore, assuming no other losses, the efficiency is Rrad / (Rrad + Rloss) = 5.7 / (5.7 + 6.85) = ~45%. However, the very low Rrad means that milliohm-level increases in Rloss can have a large effect on efficiency. For example, if Rloss increases by 5 milliohms, then the efficiency drops to 5.7 / (5.7 + 11.85) = ~32%. If Rloss increases by 10 milliohms, the efficiency drops to 5.7 / (5.7 + 16.85) = ~25%.

Given this background, the following FEM simulations were performed.

Simulated RF resistance of a solid, round-cross-section copper conductor

For this first simulation, a solid copper conductor was modeled. FEMM allows modeling a cross-sectional slice of the conductor, which is then effectively rotated about the Z axis to form a loop conductor. The complex impedance of the conductor can be computed at a given frequency, and the real part of the impedance gives the resistive losses. It is also possible to plot the flux density and current density, although this data is not extensively used in this article. We focus mainly on the computed resistive loss at 7 MHz, which includes skin effects and also proximity effects.

Conditions: Mesh resolution was set to 4 microns in a 200-micron-thickness shell at the outer edge of the copper conductor. Higher resolution was not possible due to memory limitations. Mesh resolution was set to automatic (coarser resolution) in the interior of the copper conductor, and in the air region exterior to the conductor. Simulation domain consisted of 3955864 Nodes and 7911456 Elements.

The following image shows the entire simulation domain. The circle in the middle represents the round cross-section of the conductor, which is placed at a distance (radius) of 50 cm from the central vertical axis. The simulation then effectively rotates this cross section around the vertical axis, forming a loop conductor 1 meter in diameter. The several semi-circles at the edge of the problem domain represent the boundary conditions, which were automatically generated by FEMM.

The following images zoom in successively closer to the copper conductor, showing how the problem has been configured with the highest simulation density near the surface of the conductor, to capture skin effects.

Result: RF resistance of 527.96 milliohms was computed. This is an implausible result and is too high. Examination of the simulated current density shows very high current density in the interior of the conductor, which we know analytically to be incorrect. This incorrectly-computed interior current flow, probably computed inaccurately due to the coarse mesh resolution in the interior conductor region, reduces the computed current flow in the outer shell region (which should actually be carrying all of the current), which ultimately leads to a wrong overall current density and a wrong RF resistance value.

Simulated RF resistance of a hollow, round-cross-section copper conductor

For this next simulation, the interior region of the conductor was replaced with non-conducting air, to prevent any current flow in this region. The only conductive region is the 200-micron copper shell, forming a thin-wall conductor. Since the skin depth at 7 MHz is ~25 microns, the 200-micron shell thickness covers more than 5 skin depths, which is generally considered sufficient for practically minimum RF resistance.

Conditions: Mesh resolution was set to 5 microns in the 200-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 2546258 Nodes and 5092242 Elements.

Result: RF resistance of 7.18 milliohms computed. This is in good agreement with the analytical result of 6.85 milliohms. The RF current is concentrated in the outer-most layers of the thin shell, as expected.

Simulated RF resistance of a thinner-shelled, round-cross-section copper conductor

For this next simulation, the copper shell thickness was reduced from 200 microns to 100 microns. This corresponds to only four skin depths at 7 MHz, not the typically-recommended 5 skin depths.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 3553075 Nodes and 7105877 Elements.

Result: RF resistance of 7.19 milliohms was computed. This is again in good agreement with the analytical result of 6.85 milliohms. The reduction in shell thickness from 200 microns to 100 microns results in only a negligible change in RF resistance.

Simulated RF resistance of a thin-shelled, almost perfectly square-cross-section copper conductor

For this next simulation, the copper shell shape was changed from round to almost perfectly square. Width was 100.1 mm and height was 100.4 mm. The extra height is to accommodate inserting an isolating air gap between the flat faces, for the next simulation. Shell thickness was 100 microns. To avoid computation errors and unrealistically high current crowding at sharp corners, the 90-degree corners of the square cross section were changed into rounded curves to smooth out the current flow to more realistic values (since perfectly sharp corners do not exist in physical conductors).

The following image shows the square-cross-section conductor.

The following image shows how the sharp corners of the conductor have been rounded, to avoid simulation anomalies.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4601765 Nodes and 9203200 Elements.

Result: RF resistance of 7.09 milliohms was computed. The change of conductor cross section from round to square results in only a negligible change in RF resistance. The value is still in good agreement with the analytical result of 6.85 milliohms.

Simulated RF resistance of a thin-shelled, almost perfectly square-cross-section copper conductor with isolated walls

For this next simulation, the four faces or walls of the square-cross-section conductor were disconnected from each other by inserting small air gaps at each corner. Because the current ideally should flow longitudinally along each face and along the circumference of the loop, the air gaps – which are in line with the current flow – should theoretically not hinder the current flow and should not change the RF resistance. The air gaps only prevent the current from flowing cross-wise from one face to another adjoining face. However, normally we would expect that current need not flow cross-wise from one face to another face.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4595785 Nodes and 9191231 Elements.

The following image shows how an air gap has been inserted between adjoining sides of the square-cross-section conductor.

Result: RF resistance of 7.27 milliohms was computed. The change of isolating the adjoining conductor faces by insertion of air gaps (in line with the direction of the current flow) results in only a negligible change in RF resistance. The value is still in good agreement with the analytical result of 6.85 milliohms.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with isolated walls

For this next simulation, the four isolated faces or walls of the square-cross-section conductor were distorted from the perfect square shape by randomly moving each end of each edge by a few millimeters in the x and y directions. A real physical construction of such a square-cross-section conductor may have small imperfections in the square cross-sectional shape, and the purpose of this simulation was to see if these imperfections would cause an increase in RF resistance.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4521864 Nodes and 9043451 Elements.

The following image shows the distorted, approximately-square cross-section of the conductor, with the adjacent sides still disconnected by an air gap.

Result: RF resistance of 12.27 milliohms was computed. This is a significant increase in RF resistance. A perfectly square cross-sectional shape leads to perfectly balanced current distribution among four faces, even if those faces are electrically isolated from one another. However, a distorted cross-sectional shape leads to a poorer current distribution among the faces, which, due to the inter-face isolation, can no longer redistribute itself more evenly among the faces. The resulting poor current distribution reduces the amount of the conductor that is used to carry current, hence increasing the RF resistance.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with thin copper connectors between adjoining walls

For this next simulation, the isolated faces of the distorted square-cross-section conductor were connected with each other. The hope is that by electrically connecting the isolated and misaligned faces, the poor current distribution – caused by the distorted shape and misaligned faces – can somewhat balance itself out again if the current is allowed to flow cross-wise from one misaligned face onto an adjoining misaligned face. The air gaps between the corners of the faces were bridged with a copper conductor. Again, sharp edges were changed to round edges to prevent simulation anomalies.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4824805 Nodes and 9649327 Elements.

The following image shows how the air gaps at the corners of the misaligned sides have been bridged with a copper conductor.

Result: RF resistance of 8.12 milliohms was computed. This is lower than the 12.27 milliohms of the distorted conductor with disconnected faces. Therefore, we can conclude that connecting the misaligned faces to allow cross-wise current flow between adjacent misaligned faces does improve the current distribution and does reduce the RF resistance. However, the resulting RF resistance of this misaligned and connected square-cross-section conductor is still higher than the 7.09 milliohms of the perfectly-aligned and connected square-cross-sectional conductor. So even with inter-face connections, the distortion of the cross-sectional shape still has a small, detrimental effect on the RF resistance.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with thin stainless steel connectors between adjoining walls

For this next simulation, the copper conductors that bridge the gaps between the misaligned faces were replaced with stainless steel conductors. The background to this idea is that in a physical construction of a square-cross-section conductor, the four flat faces (flat sheets of copper) can be laid separately on the outside of a square-cross-section plastic tube. This leaves four air gaps at the corners, with each gap running along the length of the square tube, and with each gap separating the the edges of two adjoining flat copper sheets. These air gaps can then be soldered for electrical connectivity. However, the electrical resistance of solder is higher than that of copper. For simulation purposes, it could be appropriate to use tin as a conductor to simulate the higher resistance of solder. However, the FEMM software does not offer tin as part of its material library. As a subsitute, 304 stainless steel (which is provided with the default FEMM material library, with conductivity specified as 1.45 MS/m) was used as a connecting material in the simulation. Steel has a much higher resistance than copper or tin, and so should provide an upper bound on the RF resistance. The expectation was that since the connecting material’s area is so small compared to the main copper conductors’ area, the impact on RF resistance should be negligible.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4825265 Nodes and 9650247 Elements.

The following image shows how the connecting corner conductor, that bridges the gap between the misaligned vertical conductor and misaligned horizontal conductor, has been changed to a steel conductor, while the main conducting areas are still configured as copper.

Result: RF resistance of 32.41 milliohms was computed. This is contrary to expectation and seems unusually high. Introducing the stainless steel connectors has actually increased the RF resistance far above the RF resistance that occurs when the faces are left unconnected. The presence of stainless steel seems to be worse than no connection at all.

Examination of the current density showed extremely high current concentration in the stainless steel regions. The cause appeared to be the insufficient thickness (100 microns) of the stainless steel conductor. 100 micron thickness covers 4 skin depths of copper at 7 MHz, but it covers less than 1 skin depth in stainless steel at 7 MHz, because the skin depth of stainless steel at 7 MHz is approximately 161 microns. To cover 5 skin depths in stainless steel requires approximately 805 microns of thickness, so another simulation was run with thicker stainless steel connectors.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with thick stainless steel connectors between adjoining walls

For this next simulation, the thickness of the conductor thickness in the stainless steel connecting areas was increased to approximately 900 microns, to cover 5 skin depths in stainless steel at 7 MHz. After thickening the connectors, the sharp corners were rounded. Copper conductors were left at 100 microns thickness. The expectation was that the current flow in the steel areas should be essentially maximal, due to the 5-skin-depth thickness, and that the overall impact on RF resistance should be small, since the circumferential length (around the conductor’s cross-sectional perimeter) occupied by the steel connectors is small compared to the circumferential length occupied by the copper conducting surfaces.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell. Mesh resolution was set to 30 microns in the approximately 900-micron-thick stainless steel connecting areas, to encompass 4 to 5 skin depths of stainless steel at 7 MHz. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4825560 Nodes and 9063542 Elements.

Results: RF resistance of 29.65 milliohms was computed. This is only a small improvement over the previous RF resistance (with thinner steel connectors) of 32.41 milliohms. Therefore, the thickness of the stainless steel connectors does not seem to be the primary cause of the increased RF resistance.

One explanation may be that the very presence of the stainless steel itself is causing the increased RF resistance. An anecdotal report that stainless steel greatly increases RF resistance can be found here: https://www.eham.net/community/smf/index.php/topic,83113.0.html.

Another alternative explanation may be that the simulation resolution in the stainless steel area (30 microns) is too coarse to compute an accurate resistance. It is not possible, in the above simulation, to increase the simulation resolution in the thick stainless steel areas, because then the mesh size exceeds the available memory. To investigate this hypothesis further, it should be possible to run a separate simulation with a thin-shelled (5 skin depths) stainless steel conductor, once with 3 micron resolution, and once with 30 micron resolution. The mesh size can be minimized to fit within available memory by reducing the conductor diameter as necessary. Then, the RF resistance can be compared between the 3-micron-resolution run and the 30-micron-resolution run. If the computed RF resistance is significantly different, this indicates that a 30-micron resolution is too coarse.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with thin aluminum connectors between adjoining walls

For this next simulation, the connecting areas were changed from stainless steel to aluminum (which is provided with the default FEMM material library, with conductivity specified as 24.59 MS/m). The problem geometry was copied from the previous test case with thin copper connectors, meaning that all conductors and connectors were set to 100 micron thickness and sharp corners were rounded in the same way as in the previous test case with thin copper connectors. 100 micron thickness should be enough to cover 3 skin depths in aluminum at 7 MHz.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell and in the 100-micron-thick aluminum connectors. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4825560 Nodes and 9650835 Elements.

Result: RF resistance of 9.71 milliohms was computed. This is higher than the 8.12 milliohms RF resistance when using thin copper connectors, but lower than the 29.65 milliohms RF resistance when using thick stainless steel connectors. It is also lower than the 12.27 milliohms RF resistance when the faces are disconnected from one another.

Simulated RF resistance of a thin-shelled, distorted square-cross-section copper conductor with thin tin connectors between adjoining walls

For this next simulation, the connecting areas were changed from aluminum to tin, to simulate the resistance of ordinary solder. The FEMM default material library does not provide a tin material. Examination of other default FEMM material library entries for copper, aluminum, and stainless steel revealed that the only parameter that is necessary to define a new material is the material's conductivity in MS/m. The conductivity of tin is 8.7 MS/m, and a new FEMM material was created with this conductivity, leaving all other material parameters as-is. The problem geometry was copied from the previous test case with thin copper connectors, meaning that all conductors and connectors were set to 100 micron thickness and sharp corners were rounded in the same way as in the previous test case with thin copper connectors. A 100 micron thickness covers slightly more than one skin depth (64.49 microns) of tin at 7 MHz.

Conditions: Mesh resolution was set to 3 microns in the 100-micron-thick copper shell and in the 100-micron-thick tin connectors. Mesh resolution was set to automatic (coarser resolution) in the air region exterior to the conductor. Simulation domain consisted of 4825560 Nodes and 9650835 Elements.

Result: RF

resistance of 12.84 milliohms was computed. This is higher than the

RF resistance when using copper or aluminum connectors, but is lower than the RF resistance when using thick

stainless steel connectors. However, the RF resistance is actually higher than the 12.27 milliohms obtained when the faces are disconnected from one another. Even higher total RF resistance would be expected if the resistivity of the solder is actually higher than that of tin,as for example shown in the resistivity table at https://owenduffy.net/antenna/conductors/loss.htm.

Summary of simulated RF resistance values

The following FEM simulation results were obtained for the RF resistance of a 10 cm diameter conductor of various configurations. These should be compared with the analytical result of 6.85 milliohms RF resistance at 7 MHz for a solid round conductor with 10 cm diameter.

- Solid 10 cm round conductor: 527.96 milliohms (wrong result)

- Hollow 10 cm round conductor with 200 micron shell: 7.18 milliohms

- Hollow 10 cm round conductor with 100 micron shell: 7.19 milliohms

- Hollow 10 cm square conductor with 100 micron shell: 7.09 milliohms

- Hollow 10 cm square conductor with disconnected 100 micron shell: 7.27 milliohms

- Hollow 10 cm square conductor with disconnected and misaligned 100 micron shell: 12.27 milliohms

- Hollow 10 cm square conductor with misaligned 100 micron shell connected by thin copper connectors: 8.12 milliohms

- Hollow 10 cm square conductor with misaligned 100 micron shell connected by thin stainless steel connectors: 32.41 milliohms

- Hollow 10 cm square conductor with misaligned 100 micron shell connected by thick stainless steel connectors: 29.65 milliohms

- Hollow 10 cm square conductor with misaligned 100 micron shell connected by thin aluminum connectors: 9.71 milliohms

- Hollow 10 cm square conductor with misaligned 100 micron shell connected by thin tin connectors: 12.84 milliohms

Conclusions

For a 1-meter-diameter loop antenna at 7 MHz, the low radiation resistance of 5.7 milliohms requires a correspondingly low-loss conductor to achieve reasonable efficiency. With a 10 cm diameter conductor, a square-cross-section conductor – which in some respects is easier to fabricate than a round-cross-section conductor – can provide sufficiently low RF resistance.

However, small details of the conductor geometry can cause significant changes in the overall RF resistance. This is important because fabricating a 10 cm-wide square-cross-section conductor by hand, by separately assembling several flat sheets of copper, will inevitably lead to small misalignment among the faces and distortions from the ideal, perfectly-shaped, square cross-section.

If the flat sides of the square cross-section conductor are galvanically isolated from one another, then small misalignment, on the order of a few millimeters, of the flat sides of the square-cross-section conductor can lead to significant increases of RF resistance.

If the misaligned flat sides of the square-cross-section conductor are connected to each other with copper, the RF resistance decreases to acceptable levels (only slightly above that of the perfectly-aligned case) because the current is allowed to flow cross-wise from one misaligned face to an adjoining misaligned face, which will improve current distribution and reduce the conductor’s RF resistance.

However, if the misaligned flat sides of the square-cross-section conductor are connected to each other with low-conductivity stainless steel, the RF resistance significantly increases to unacceptably high levels -- higher than if the faces were left unconnected.

If an aluminum conductor is used to connect the misaligned flat sides, then the RF resistance lies between that of copper connectors and that of stainless steel connectors.

If a tin conductor is used to connect the misaligned flat sides, then the RF resistance is comparably high to the case where the flat sides are left disconnected.

Therefore, the material used to connect the misaligned flat sides of the square-cross-section conductor will have an influence on the overall RF resistance. In practice, tin solder, with a resistivity similar to that of tin, will be the most likely material used to connect the faces. In the above simulations, using tin solder to connect misaligned faces was found to have no benefit over leaving the misaligned faces disconnected.

Further studies with varying amounts of misalignment would be needed to clarify whether there are any cases where soldering misaligned faces would bring any benefit, but the current results suggest there will be minimal, if any, benefit.

A likely more beneficial strategy would consist of two points. First, attempt to avoid misalignment of the cross-sectional shape from a perfect square or perfect circle; this can be done with a rigid former and/or with thick copper that is less subject to deformation, but both of these measures increase the weight and the difficulty of working with the materials. Second, avoid separating the faces in the first place, by avoiding the use of four separate copper sheets to form four separated flat faces of one tube, and instead rolling a continuous copper sheet into a large-diameter tube. This again is more difficult to construct (since a single and large copper sheet must be rolled to yield a perfectly circular or square cross-sectional shape), but likely will yield the lowest RF resistance for the conductor. This roll-up construction would still leave one unconnected seam along the tube's length. The effect of this seam is likely minimal, but a simulation should be performed to confirm this.